Chang-Yu Sun, László Gránásy1,2, Cayla Stifler, Tal Zaquin, Rajesh Chopdekar, Nobumichi Tamura, James Weaver, Jun Zhang, Stefano Goffredo, Giuseppe Falini, Matthew Marcus, Tamás Pusztai1, Vanessa Schoeppler3, Tali Mass, Pupa Gilbert

1Institute for Solid State Physics and Optics, Wigner Research Centre for Physics, P.O. Box 49, Budapest H-1525, Hungary

2BCAST, Brunel University, Uxbridge, Middlesex, UB8 3PH, United Kingdom

3B CUBE - Center for Molecular Bioengineering, Technische Universität Dresden, Germany

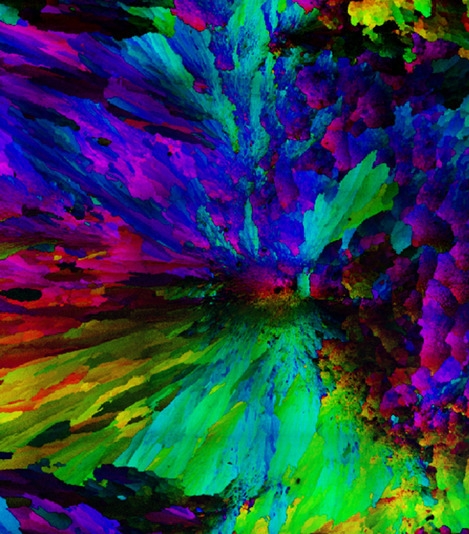

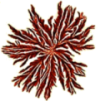

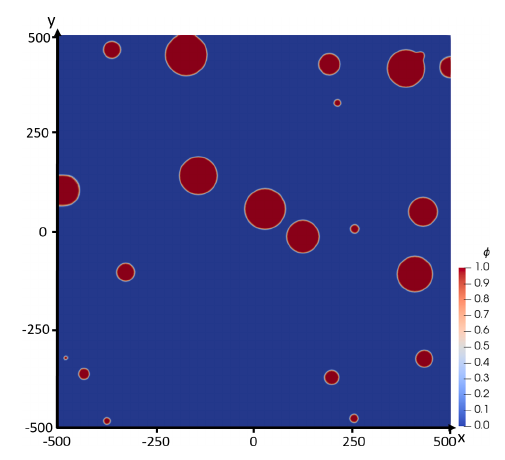

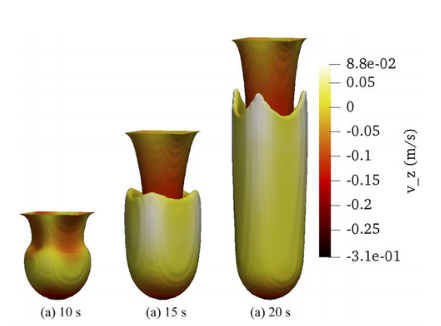

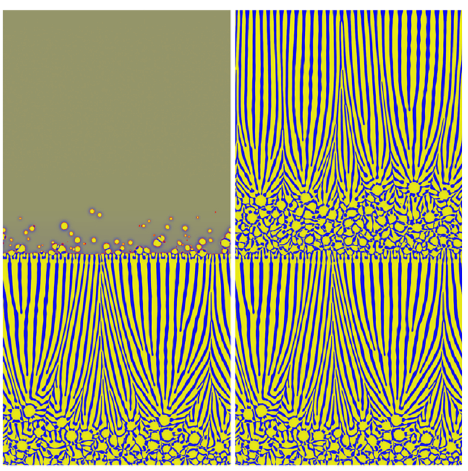

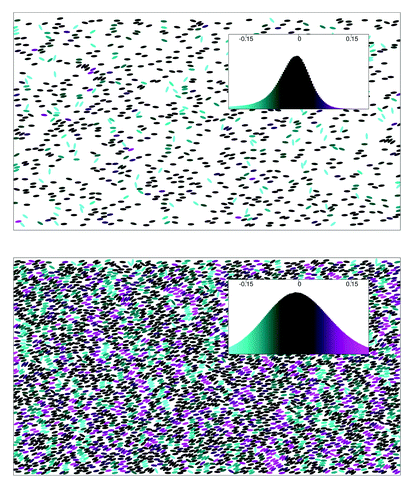

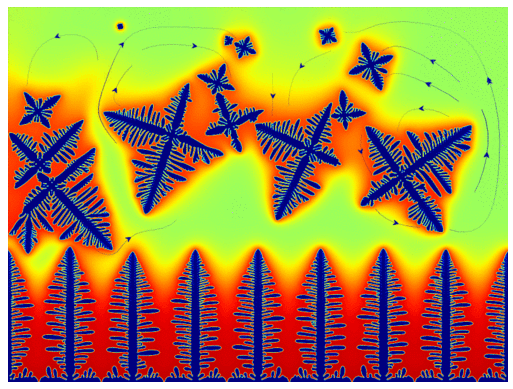

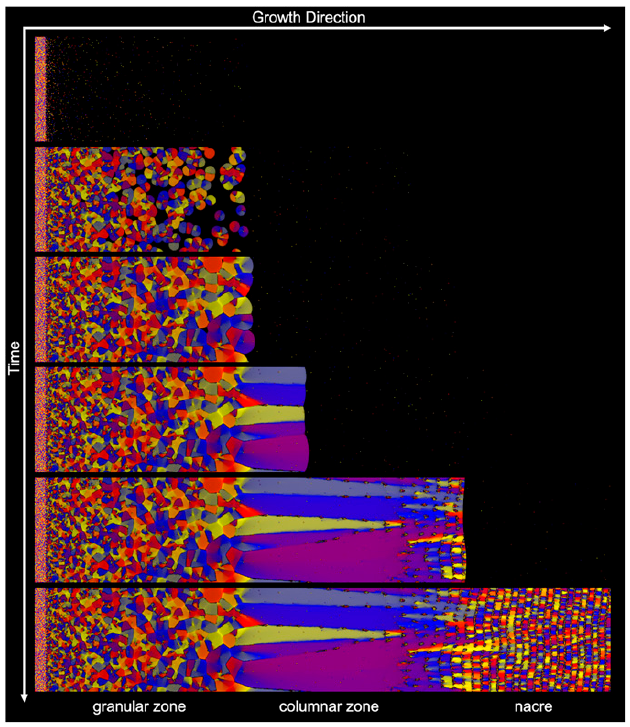

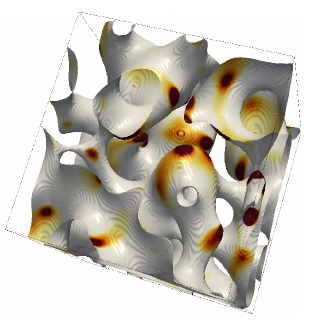

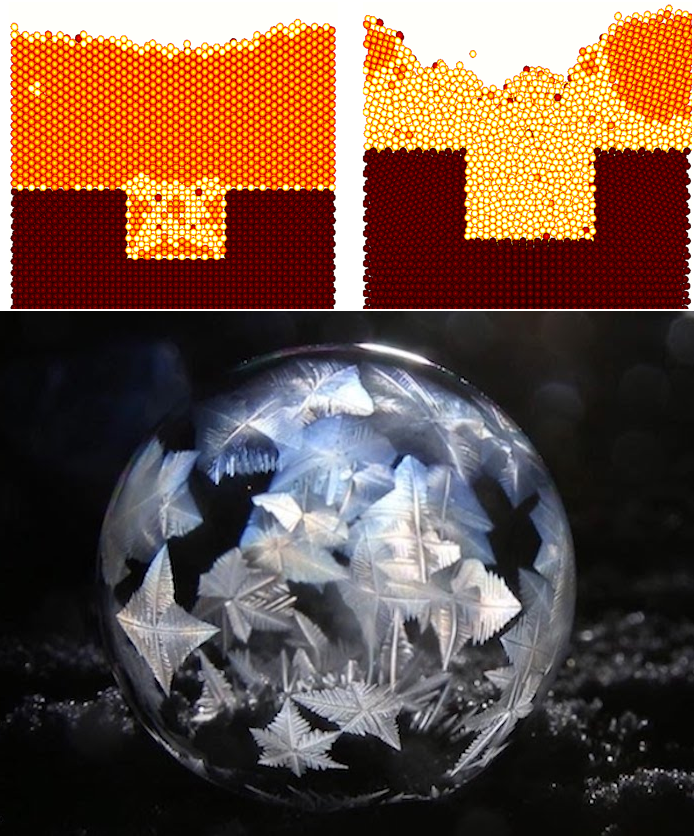

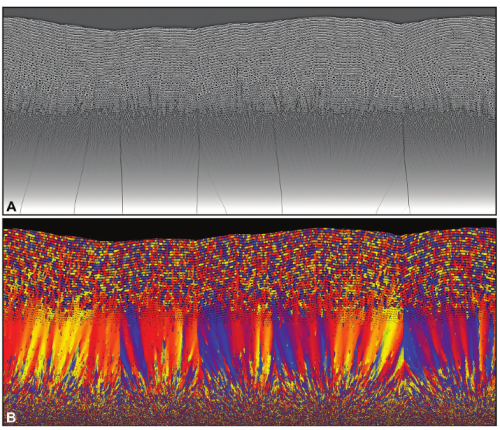

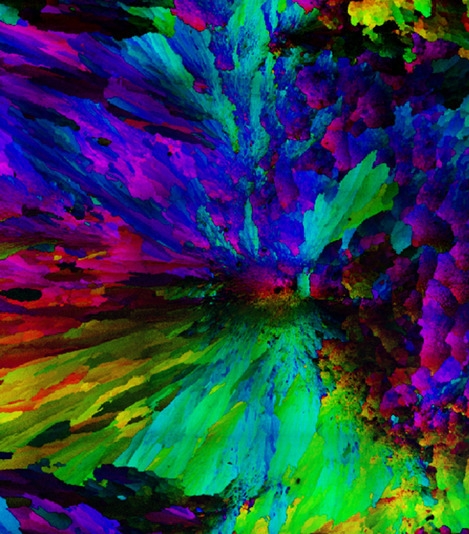

Spherulites are radial distributions of acicular crystals, common in biogenic, geologic, and synthetic systems, yet exactly how spherulitic crystals nucleate and grow is still poorly understood. To investigate these processes in more detail, we chose scleractinian corals as a model system, because they are well known to form their skeletons from aragonite (CaCO3) spherulites, and because a comparative study of crystal structures across coral species has not been performed previously. We observed that all 12 diverse coral species analyzed here exhibit plumose spherulites in their skeletons, with well-defined centers of calcification (CoCs), and crystalline fibers radiating from them. In 7 of the 12 species, we observed a skeletal structural motif not observed previously: randomly oriented, equant crystals, which we termed “sprinkles”. In Acropora pharaonis, these sprinkles are localized at the CoCs, while in 6 other species, sprinkles are either layered at the growth front (GF) of the spherulites, or randomly distributed. At the nano- and micro-scale, coral skeletons fill space as much as single crystals of aragonite. Based on these observations, we tentatively propose a spherulite formation mechanism in which growth front nucleation (GFN) of randomly oriented sprinkles, competition for space, and coarsening produce spherulites, rather than the previously assumed slightly misoriented nucleations termed “non-crystallographic branching”. Phase-field simulations support this mechanism, and, using a minimal set of thermodynamic parameters, are able to reproduce all of the microstructural variation observed experimentally in all of the investigated coral skeletons. Beyond coral skeletons, other spherulitic systems, from aspirin to semicrystalline polymers and chocolate, may also form according to the mechanism for spherulite formation proposed here.